VFD Display Tube Code - Clock

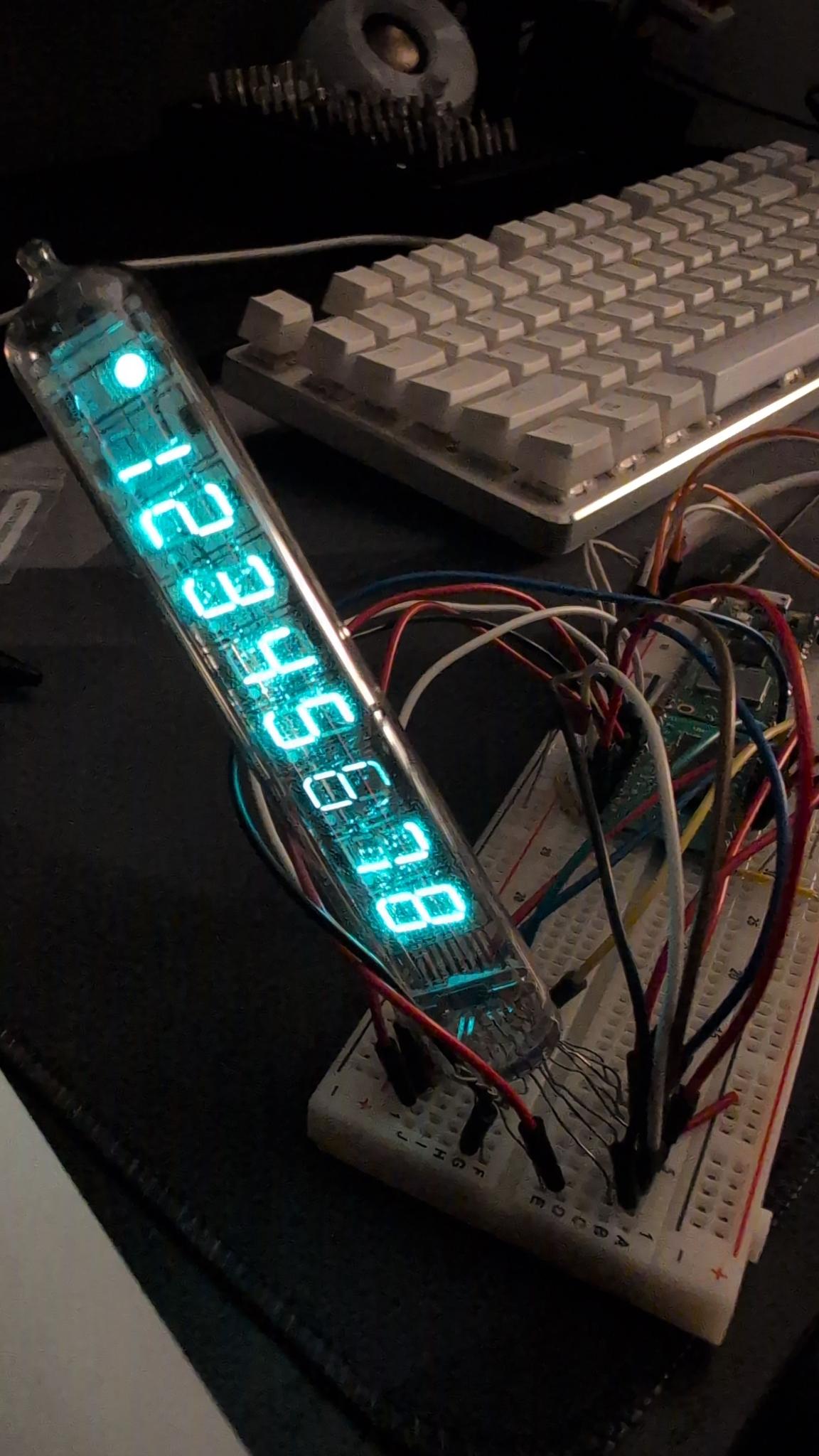

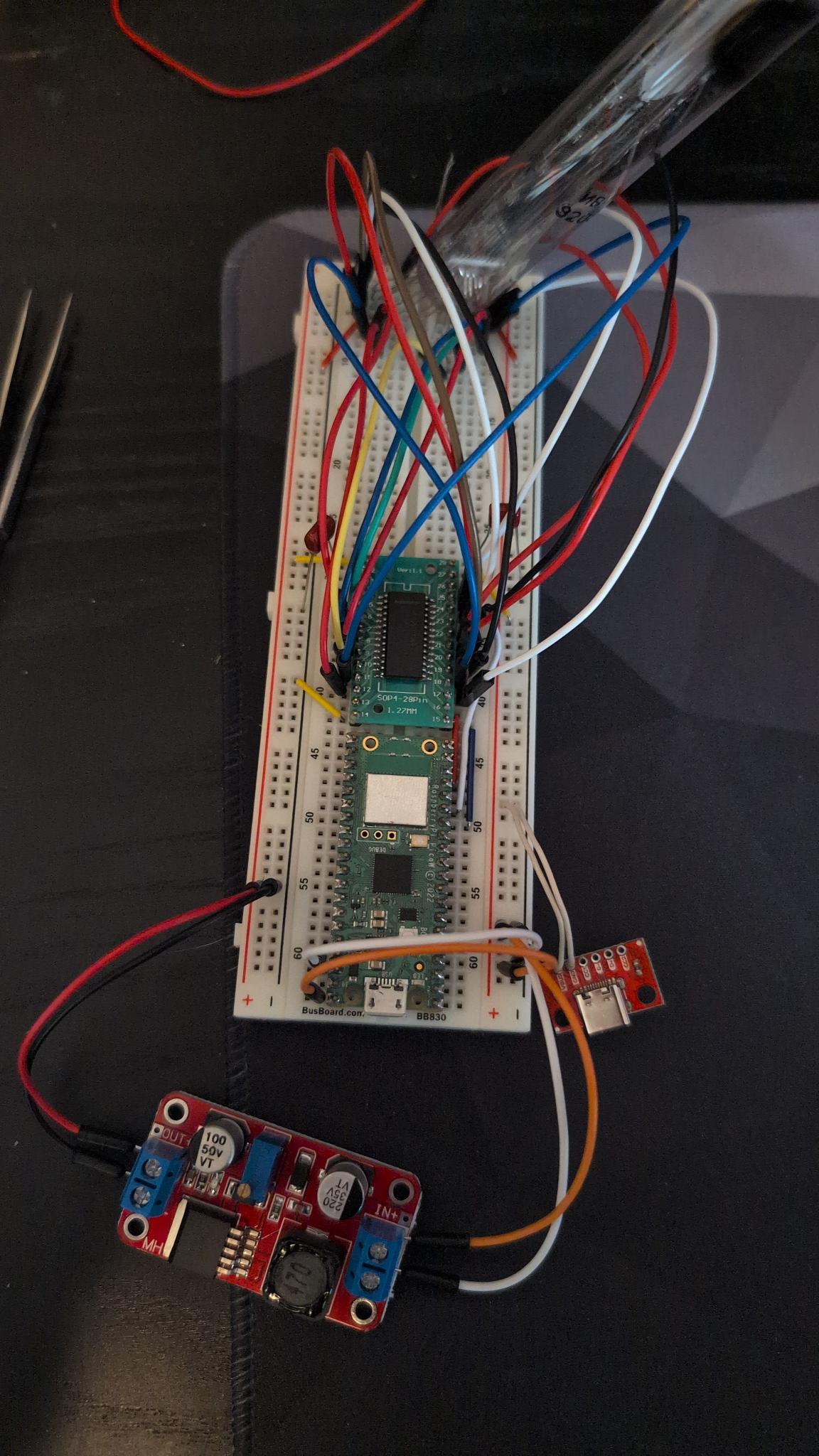

Overview This project demonstrates how to drive a VFD (Vacuum Fluorescent Display) using a Raspberry Pi Pico W and the MAXIM MAX6921AWI chip. The display setup includes a 7-segment display with a decimal point and 8 grids, controlled using a 20-bit buffer, leaving room for additional control logic. The VFD of choice this time around is the Soviet (Sovtek) IV-18 a.k.a ИВ-18 (Совтек).

Pin Mapping and Layout

Mapping Layout

- Display Details:

- The display consists of a 7-segment display + 1 dot (decimal point).

- There are

89 grids (digits), requiring1617 pins for control (8 segment pins +89 grid pins). - Only one grid pin is active high at a time, leaving

43 unused bits, which can be reserved for future use.

- Pin Mapping:

- Pins 0–7: Drive the segments (7-segment + dot).

- Pins 8–16: Control the grids (digits).

- Buffer Details:

- This setup uses 2 bytes + 1 bit (

1617 bits), but the MAXIM MAX6921AWI chip requires 20 bits. - The

43 remaining bits can be padded or reserved for control logic. - The chip’s clear pin can be triggered via the Pico, potentially using the last 4 output pins.

Voltage Note: Driving the clear pin requires careful consideration of the bus voltage (e.g., 25V for IV-18). A resistor ladder can step down voltages if needed.

- This setup uses 2 bytes + 1 bit (

VFD Segment Display Matrix

Physical VFD Pin Mapping:

-- <- Top segment (Pin 12)

| | <- Left (Pin 11) and Right (Pin 10) middle segments

-- <- Middle segment (Pin 9)

| | <- Left (Pin 5) and Right (Pin 4) bottom segments

-- . <- Bottom segment (Pin 3) and decimal point (Pin 2)

Logical Segment Mapping (A–H):

-- <- Segment A (Top)

| | <- Segments F (Left) and B (Right)

-- <- Segment G (Middle)

| | <- Segments E (Left) and C (Right)

-- . <- Segment D (Bottom) and H (Decimal point)

Alphanumeric Segment Pinout:

| VFD Pin | Segment |

|---------|---------|

| Pin 12 | A |

| Pin 11 | F |

| Pin 10 | B |

| Pin 9 | G |

| Pin 5 | E |

| Pin 4 | C |

| Pin 3 | D |

| Pin 2 | H (Decimal Point) |

| Pin 1, 13 | Heating elements (not coded) |

Control Logic and Commands

The remaining 4 3 bits of the 20-bit buffer can be used for control logic. Here is the mapping of the control bits:

Control Bits Command Table

| Decimal | Binary | Hexadecimal | Command Description |

|---|---|---|---|

| 0 | 000 | 0x0 | N/A |

| 1 | 001 | 0x1 | N/A |

| 2 | 010 | 0x2 | N/A |

| 3 | 011 | 0x3 | N/A |

| 4 | 100 | 0x4 | N/A |

| 5 | 101 | 0x5 | N/A |

| 6 | 110 | 0x6 | N/A |

| 7 | 111 | 0x7 | N/A |

/*********************************************************************************

* Authors: Aidan Bradley and Andrew Korman

* Years: 2024-2025

*

* Description:

* This program was written in C to drive a triode-based Vacuum Fluorescent Display

* (VFD) system using the Maxim MAX6921 VFD driver chip. The code is designed for

* use on the Raspberry Pi Pico microcontroller and utilizes the SPI interface to

* communicate with the VFD chip. It implements real-time clock (RTC) functionality

* for timekeeping and allows user interaction via button inputs for setting hours,

* minutes, and seconds.

*

* Key Features:

* - Real-time clock functionality for dynamic time display.

* - Button-based input for adjusting time with debounce handling.

* - SPI communication to drive the MAX6921 VFD chip.

* - Seven-segment display formatting with control over segment illumination and

* grid selection.

* - Modular and well-commented functions for initializing hardware, updating the

* VFD, and managing user input.

*

* Dependencies:

* - Raspberry Pi Pico SDK

* - Standard C libraries: stdio.h, string.h

* - Hardware-specific libraries: pico/stdlib.h, hardware/spi.h, hardware/rtc.h

*

* Note:

* This code assumes a specific hardware setup, including pin assignments for SPI,

* latch, and button inputs. Ensure proper connections and configurations when

* deploying this code.

*

* Disclaimer:

* This code was developed by Aidan Bradley and Andrew Korman and is provided as-is.

*********************************************************************************/

#include <stdio.h>

#include <string.h>

#include "pico/stdlib.h"

#include "pico/binary_info.h"

#include "hardware/spi.h"

#include "hardware/rtc.h"

#include "pico/util/datetime.h"

// Define pin connections

const uint SPI_D = 11; // MOSI (SPI TX)

const uint SPI_C = 10; // SCK (SPI Clock)

const uint SPI_L = 13; // Latch pin (GPIO)

const uint BPID1 = 16; // Button 1 Pin ID

const uint BPID2 = 17; // Button 2 Pin ID

// SPI configurations

#define SPI_PORT spi1 // Using SPI1 interface

#define SPI_BAUDRATE 2000000 // 2 MHz

// Segment control and grid control arrays

uint8_t segment_control[] = {

0b00111111, // 0: A B C D E F

0b00000110, // 1: B C

0b01011011, // 2: A B D E G

0b01001111, // 3: A B C D G

0b01100110, // 4: B C F G

0b01101101, // 5: A C D F G

0b01111101, // 6: A C D E F G

0b00000111, // 7: A B C

0b01111111, // 8: A B C D E F G

0b01101111, // 9: A B C D F G

0b10000000, // decimal: H (10)

0b01000000, // dash: G (11)

0b00000000 // blank (12)

};

uint16_t grid_control[] = {

0b100000000, // grid 0 (decimal)

0b010000000, // grid 1

0b001000000, // grid 2

0b000100000, // grid 3

0b000010000, // grid 4

0b000001000, // grid 5

0b000000100, // grid 6

0b000000010, // grid 7

0b000000001 // grid 8

};

uint8_t state[9] = {

12, // decimal

12, // hourleft

12, // hourright

11, // dash

12, // minleft

12, // minright

11, // dash

12, // secleft

12 // secright

};

// define global variables

uint8_t data[3];

uint8_t digit;

uint8_t grid;

uint32_t combined_data;

bool button_state[]={false, false};

// define datetime struct

datetime_t t = {

.year = 2000,

.month = 06,

.day = 05,

.dotw = 5, // 0 is Sunday, so 5 is Friday

.hour = 01,

.min = 59,

.sec = 45

};

// function to update the vfd

void write_vfd(uint8_t digit, uint8_t grid) {

combined_data = (grid_control[grid] << 8) | segment_control[digit];

data[0] = (combined_data >> 16) & 0xFF;

data[1] = (combined_data >> 8) & 0xFF;

data[2] = combined_data & 0xFF;

spi_write_blocking(SPI_PORT, data, 3);

gpio_put(SPI_L, 1);

sleep_us(1);

gpio_put(SPI_L, 0);

}

void init_gpio(uint bpid1, uint bpid2){

stdio_init_all(); // initial std i/o setup

gpio_pull_down(bpid1);

gpio_pull_down(bpid2);

spi_init(SPI_PORT, SPI_BAUDRATE);

gpio_set_function(SPI_C, GPIO_FUNC_SPI);

gpio_set_function(SPI_D, GPIO_FUNC_SPI);

gpio_init(SPI_L);

gpio_set_dir(SPI_L, GPIO_OUT);

}

void double_debounce(uint GPIO1, uint GPIO2) {

bool first1 = gpio_get(GPIO1);

bool first2 = gpio_get(GPIO2);

sleep_ms(1);

bool second1 = gpio_get(GPIO1);

bool second2 = gpio_get(GPIO2);

if ((first1 && second1) && (first2 && second2)){

button_state[0] = true;

button_state[1] = true;

}

else if ((first1 && second1) && (!first2 && !second2)){

button_state[0] = true;

button_state[1] = false;

} else if ((!first1 && !second1) && (first2 && second2)){

button_state[0] = false;

button_state[1] = true;

} else {

button_state[0] = false;

button_state[1] = false;

}

}

int main() {

init_gpio(BPID1, BPID2);

rtc_init();

rtc_set_datetime(&t);

sleep_ms(1000);

uint8_t counter = 0;

bool setmode = false;

int setcode = 0;

while (1) {

double_debounce(BPID1, BPID2);

if ((button_state[0]) && !setmode){

setmode = true;

} else if ((button_state[0]) && setmode) {

if (setcode < 2){

setcode += 1;

} else if (setcode >= 2){

setcode = 0;

setmode = false;

}

}

if ((button_state[1]) && setmode) {

if ((setcode == 0) && (t.hour <= 23)){

t.hour += 1;

} else if ((setcode == 0) && (t.hour == 24)){

t.hour = 0;

}

if ((setcode == 1) && (t.min <= 59)){

t.min += 1;

} else if ((setcode == 1) && (t.min == 60)) {

t.min = 0;

}

if ((setcode == 2) && (t.sec <=59)){

t.sec += 1;

} else if ((setcode == 2) && (t.sec == 60)) {

t.sec = 0;

}

}

rtc_get_datetime(&t);

if (t.hour >= 12) {

state[0] = 10;

} else {

state[0] = 12;

}

if ((t.hour == 0) && (!setmode)) {

t.hour = 12;

}

else if (t.hour > 12) {

t.hour -= 12;

}

if (t.hour < 10) {

state[1] = 12;

}

else {

state[1] = (t.hour / 10);

}

state[2] = (t.hour % 10);

state[4] = (t.min / 10);

state[5] = (t.min % 10);

state[7] = (t.sec / 10);

state[8] = (t.sec % 10);

write_vfd(state[counter], counter);

counter ++;

if (counter == 9) {

counter = 0;

}

sleep_us(1500);

}

}

- Sending data via SPI to the Maxim chip requires the data to be loaded backwards, hence sending the high byte first

- Data separately to that, the data must be sent LSB style via SPI, which was taken care of by swapping the order of the predefined segment and grid code

- With the data flipped appropriately, and the byte order sent backwards, we achieve intercommunication with the VFD driver chip

- Data segments are 0-9, so you must reverse them 9-0. Grid segments are the same. It should read PADDING + GRIDCONT + SEGMCONT => CONTR-SEQ

- CONTR-SEQ is split into three bytes, then sent VIA SPI bus.

- SPI does not have a 3rd wire, but since the maxim chip does not display any output until the latch pin is triggered, we added a 3rd pin for sending a latch signal to. It is pretty fast, so 1 microsecond was used as a buffer between setting it high and then back to low